Warm Up Your Space with Radiant Heat Tubing in Concrete

Why Installing Radiant Floor Heating in Concrete Slab Is a Smart Choice

Installing radiant floor heating in concrete slab is one of the most effective and luxurious ways to heat your home, combining unparalleled comfort with impressive energy efficiency. Unlike traditional forced-air systems that heat the air, radiant systems warm the floor and the objects in the room directly. This creates a gentle, even warmth that rises naturally from the ground up, much like the feeling of sunlight. The result is a consistently comfortable environment without cold spots or drafts.

Here are some of the key benefits that make slab-on-grade radiant heating a superior choice:

- Best Comfort: Radiant heat warms people and objects directly, providing a deep, pervasive warmth that eliminates cold floors forever. Because it doesn't rely on blowing air, it avoids the drafts and uneven temperatures common with furnaces.

- Superior Energy Efficiency: By delivering heat directly where it's needed most—at the floor level—radiant systems allow you to feel comfortable at a lower thermostat setting. This, combined with less heat loss through the ceiling, can reduce energy costs by 20-30% compared to forced-air systems. The concrete slab itself becomes a thermal mass, storing heat and releasing it slowly, which further improves efficiency.

- Silent, Peaceful Operation: With no noisy fans, blowers, or ductwork, radiant floor heating operates in complete silence, contributing to a more peaceful and tranquil home environment.

- Improved Indoor Air Quality: Forced-air systems can circulate dust, allergens, and other airborne pollutants throughout your home. Since radiant heat doesn't move air, it's an excellent choice for households with allergy sufferers or anyone concerned with indoor air quality.

- Minimal Maintenance: Once installed, the heating elements (cables or PEX tubing) are encased in the concrete slab, protecting them from damage. These systems are known for their durability and require very little maintenance over their long lifespan.

Key Steps for a Successful Installation

A high-performance radiant heating system depends on a meticulous installation process. Each step is critical for ensuring long-term reliability and efficiency.

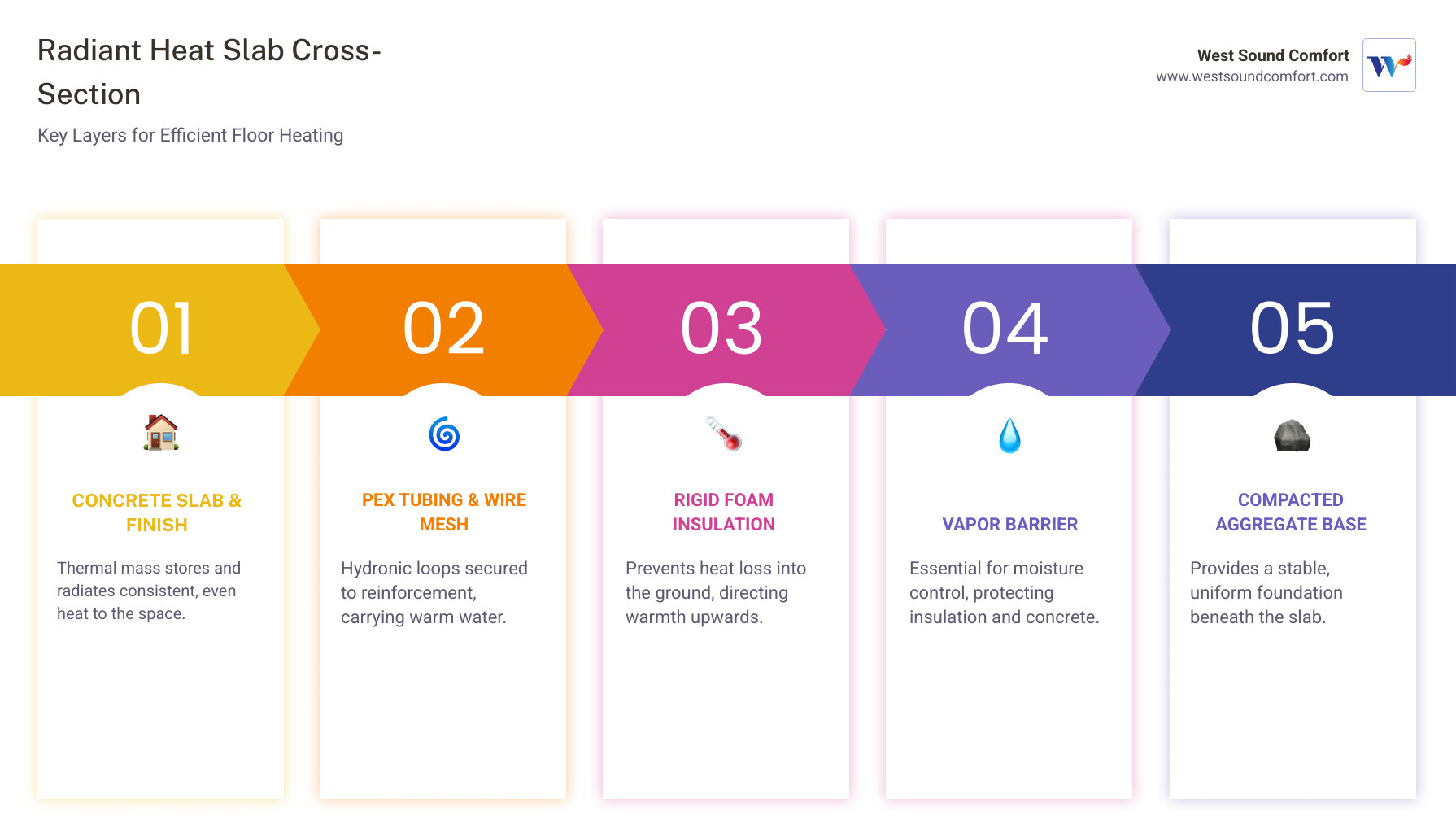

- Prepare the Base: Before any heating elements are laid, the ground must be properly prepared. This includes a stable, compacted base, a vapor barrier to block moisture from the ground, rigid insulation (at least 2" of XPS is recommended) to prevent heat from escaping downwards, and reinforcement like wire mesh or rebar.

- Layout Heating Elements: Whether using electric cables or hydronic PEX tubing, the layout must be carefully planned based on a professional heat loss calculation. The spacing, typically 8-16 inches on center, is customized to ensure every area of the room receives adequate, even heat.

- Secure the System: The tubing or cables must be securely fastened to the wire mesh or rebar reinforcement. This prevents them from "floating" to the surface or shifting during the concrete pour, which could lead to uneven heating or damage.

- Pressure Test (for Hydronic Systems): Before the concrete is poured, hydronic systems must be pressurized (typically to 50 PSI or higher, depending on local codes) and monitored for any drop in pressure. This crucial quality-control step identifies any potential leaks while they are still easy to fix.

- Pour Concrete: The concrete slab, typically 4-6 inches thick, is carefully poured to embed the heating elements at the correct depth (usually 2-3 inches from the surface). The crew must take care not to damage the system during this process.

- Cure and Activate: Concrete must be allowed to cure fully according to the manufacturer's specifications, which can take several weeks. Once cured, the heating system should be activated gradually, slowly increasing the temperature to prevent thermal shock to the new slab.

The system is particularly effective in the Pacific Northwest, where damp concrete slabs in basements, garages, and workshops can create cold, uncomfortable spaces. Whether you're building a new home in Gig Harbor or pouring a fresh slab for a workshop in Port Orchard, embedding radiant heating during construction is far more cost-effective than retrofitting later.

As Ernie Bogue, co-owner of West Sound Comfort Systems, I've spent over three decades specializing in hydronic heating systems, and installing radiant floor heating in concrete slab has been one of the most rewarding applications I've worked with throughout my career. Every installation is different, which is why proper system design and professional expertise matter so much for long-term comfort and performance.

Planning Your Radiant Heat Installation: Key Considerations

Starting on the journey of installing radiant floor heating in concrete slab requires careful and detailed planning. The choices made during these initial stages will profoundly impact the system's performance, efficiency, and your long-term comfort. At West Sound Comfort Systems, we always emphasize a thorough evaluation of your specific needs and the unique characteristics of your property, whether you're in Bremerton, Silverdale, or Sequim.

For new construction projects, installing radiant heating during the initial concrete pour is the ideal scenario. It is the most cost-effective and highest-performing application, as the system becomes an integral part of the building's structure. The thermal benefits are unsurpassed, and we often recommend embedding radiant tubing even if you don't have immediate plans to activate the heating for that space. This foresight, known as "roughing in," can prevent future regret and the much higher costs and complexities associated with retrofitting. In new builds, system zoning—dividing your home into distinct areas controlled by individual thermostats—is easily integrated into the design, allowing for customized comfort and maximum energy savings.

However, retrofitting an existing concrete slab, such as in a basement or garage conversion, also offers significant benefits. While it involves more preparation, such as pouring a thin, new layer of concrete over the existing slab, the comfort gained from changing a cold, damp space into a warm, inviting one is invaluable.

It's also crucial to be aware of local building codes and regulations. These can vary significantly, even within our service areas like Kitsap, Pierce, Mason, Clallam, and Jefferson Counties. A professional contractor will ensure all work is compliant. For instance, some jurisdictions may require a 100 PSI pressure test for hydronic tubing before the concrete pour, while others have different specifications for insulation R-values.

A professional heat-loss analysis is a non-negotiable first step. This detailed assessment calculates how much heat your home loses through walls, windows, ceilings, and floors. It considers factors like insulation levels, window efficiency, building orientation, and local climate data. This analysis allows us to accurately size your radiant heating system, ensuring it is powerful enough to provide adequate warmth on the coldest days without being oversized and wasteful.

The thermal mass of a concrete slab is one of its greatest assets for radiant heating. Concrete is excellent at storing heat and releasing it slowly and evenly, creating a consistent, stable warmth that permeates the entire space. This characteristic also means the system has a longer heat-up time compared to systems installed closer to the finished floor surface. However, it also has a longer cool-down time, providing a stable temperature and continuing to radiate heat even after the thermostat is satisfied. Understanding this behavior is key to operating the system efficiently. For example, if you're considering our comprehensive HVAC Services for a new build, integrating radiant floor heating can dramatically improve overall home comfort and efficiency.

Choosing Between Electric and Hydronic Systems

When considering installing radiant floor heating in concrete slab, a key decision involves selecting between electric and hydronic systems. Both offer the undeniable comfort of warm floors, but they serve different purposes and come with distinct installation requirements, operating characteristics, and long-term costs. The choice largely depends on the size of the area to be heated and your overall heating strategy.

| Feature | Electric Radiant Floor Heating | Hydronic Radiant Floor Heating |

|---|---|---|

| Best Use Case | Smaller areas like bathrooms, kitchens, or entryways. Excellent for supplemental heat or single-room projects. | Large areas, multiple rooms, or whole-home heating. Ideal as a primary heat source. |

| Initial Cost | Lower upfront investment. The materials (cables or mats) are less expensive. | Higher upfront investment. Requires a boiler or water heater, pumps, manifolds, and extensive tubing. |

| Operating Cost | Higher operating costs, as electricity is generally more expensive than natural gas or propane. | Lower long-term operating costs, especially for large areas, due to the efficiency of modern boilers and water's heat-carrying capacity. |

| Installation | Simpler and faster to install. Thin cables or mats are laid out and connected to the home's electrical system. | More complex installation requiring a dedicated mechanical space for the boiler and pumps, plus skilled plumbing and routing of PEX tubing. |

| System Components | Heating cables or mats, thermostat (often with a floor sensor), and electrical circuit with GFCI protection. | PEX tubing, a heat source (boiler, water heater), circulation pumps, and a distribution manifold to control water flow to different zones. |

| Heat-Up Time | Generally faster to heat up, especially when installed in a thin-set mortar bed closer to the surface. | Slower to heat up due to the large thermal mass of the concrete slab and the water in the system. |

| Maintenance | Virtually maintenance-free. The primary component to check is the thermostat. | Requires periodic maintenance, including annual inspection of the boiler, pumps, and valves to ensure optimal performance. |

In summary, electric systems are a fantastic solution for adding a touch of luxury and comfort to smaller, specific areas. For those planning to heat an entire basement, a large workshop, or a whole new home in areas like Bainbridge Island or Port Townsend, a hydronic system is almost always the more efficient and cost-effective choice in the long run. A professional consultation can help you weigh these factors and select the perfect system for your project.